- Home

- About Us

- Blog

- Capabilities

Sub-Processes

Plastic Materials

Processes Available

Post Processing

- Contact Us

One of the most crucial steps in the production process is FAI. It is speaking of the initial article inspection. The initial sample created following the conclusion of mold growth is the first article. The initial article inspection is referred to as the first article’s three-dimensional measurement. Many customers demand parts to comply to stringent criteria and within certain tolerances since they are concerned about the quality of their products, which will assure consistency in their offerings. Similar to this, suppliers who send products to several purchasers frequently want verification at the beginning of the transaction to ensure there are no issues later on.

There are frequently design changes, process changes, process adjustments, unanticipated line stoppage, production changes, line changes, and other activities during the design and manufacture of any product. The initial article inspection is necessary during the operation preparatory stage of verification and after shutdown to verify that these actions won’t damage the quality of the succeeding production.

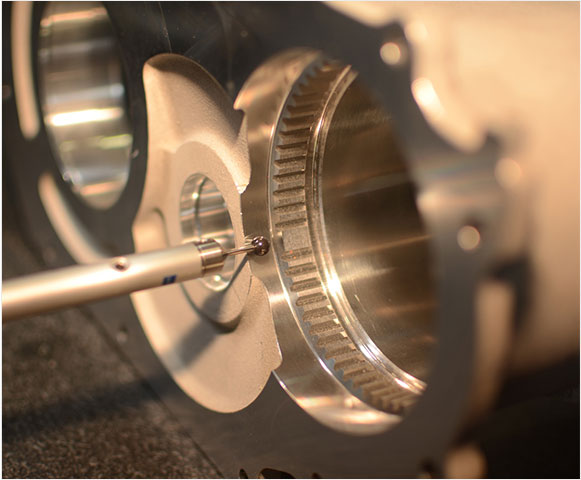

Ipqcco can provide quality inspection services to ensure that components were confidently made, regardless of whether you need to inspect incoming components from a source or are confirming parts from your own production process. Our team makes use of cutting-edge tools to assess how closely various products correspond to specifications. Ipqcco, a third-party provider of first article inspections, provides the reporting you require from precision measurement experts you can rely on.

Why Choose Ipqcco For First Article Inspections?

Contact us today to discuss your project!